eddy current hardness testing equipment|who does eddy current testing : company Our eddy current test systems easily integrate into production lines to enable instant verification of cutting, forming, and heat-treating processes for every part that comes off your line. Serving the inspection needs of automotive and . webDeseja ver a localização do estabelecimento no mapa? Clique no ver no mapa e veja onde 1000 Grau Choperia e Espetaria Itaim localiza-se, trace a rota e vejá como chegar no endereço Rua Tibúrcio de Sousa, 37 - Itaim Paulista, São Paulo - SP, 08140-000.Restaurantes perto de mim. Veja mais Restaurantes em São Paulo! Veja mais .

{plog:ftitle_list}

WEB15 de fev. de 2024 · 274 Likes, TikTok video from IG: JAKSPORT.INDO 🇲🇨 (@jaksport.indo): “valid kah maniesz? 🤣 #adipure11pro #footballboots #sepatubola”. sepatu paling dipuja .

Eddy current is a quick, simple, and reliable inspection technique that can identify abnormalities on a mass level. Finally, eddy current testing is portable, making use of small and light equipment—ideal characteristics when inspection is required throughout a production process.Eddy current testing equipment must be tailored for hardness testing. .Discover precision and reliability with ibg's innovative Eddy Current Testing technology. Detect grinder burn and cracks, revolutionize ball inspection with AVIKO's high-speed scanner, and .Digital eddy current test instrument for one-channel nondestructive testing of metal components, mass-produced parts, and semi-finished products .

Our eddy current test systems easily integrate into production lines to enable instant verification of cutting, forming, and heat-treating processes for every part that comes off your line. Serving the inspection needs of automotive and .Why Should I Use Eddy Current Technology for Hardness Testing? Eddy current testing is a contactless nondestructive method, so analysts don’t have to worry about damaging the asset or wasting any materials or resources. Eddy current testing equipment provides extraordinary sensitivity and accuracy when it comes to finding surface and near .

Eddy current testing is a non-destructive method for testing metal surfaces for defects such as longitudinal and transverse cracks. The type of testing performed, using comprehensive through-type coils or rotating probes, .Eddy current inspection is a widely accepted NDT method that uses electromagnetism for rapid, easy and cost-effective scanning of welded structures, raw materials and finished products in order to detect surface and sub-surface flaws. Get in touch today to find out more about our range of eddy current NDT inspection tools.

who does eddy current testing

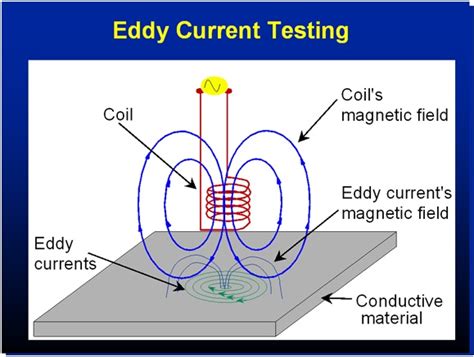

The micro-hardness profile was measured with a Knoop indenter on a Leco micro-hardness tester. For each modality of austenitizing time, five indentations were performed under a load of 1 N in a cross section perpendicular to the surface, every 20 μm from the surface to a depth of 700 μm.The eddy current equipment used was the Alphatest OMEGA 2000, which .In its most basic form — the single-element eddy current testing probe — a copper wire is excited with an alternating electrical current. This wire produces a magnetic field around itself in the direction ascertained by the right-hand rule. This magnetic field oscillates at the same frequency as the current running through the coil. Eddy Current for Hardness Testing . Eddy current for hardness testing calls for a solution that highlights irregularities on an assembly line. With eddy current, analysts don’t have to worry about destructive testing measures that waste materials. A hardness testing campaign should include sophisticated equipment that roots out abnormalities .

Features. Advanced Eddy Current Technology: Our Eddy Current testing Machine Instruments utilize the latest in Eddy current testing technology to accurately identify and sort materials based on their hardness and material properties. User-Friendly Interface: Our Eddy Current testing Machine Equipment is designed with the end user in mind, featuring .

The principle involves the generation of alternating current within a coil or conductor, engendering a dynamic magnetic field in its vicinity. When this energized coil approaches a conductive material, such as a metal component, it imparts within the material circulating electric currents – referred to as "eddy currents."Eddy current hardness testing is one of the best NDT methods used for this purpose. . These eddy current testing equipment, parts or tools work together to generate and detect eddy currents, analyse the results, and identify any defects .BKN is a leading high-tech company and manufacturer specializing in developing types of non destructive testing instruments and equipment in China, mainly including eddy current, ultrasonic, magnetic flux leakage and various non-standard equipment. Strong R&D and Production Capacity.Eddy current testing equipment is highly portable, reliable and can detect very small cracks. Results are instant, ideal for on-site testing on-site and plant inspections. Flaws can be reported immediately to site and operation managers, allowing for quicker decision making. . and metal sorting by grade and hardness. .

Like most test and measurement equipment, non-destructive testing equipment needs to be periodically calibrated to maintain accuracy. In the case of NDT equipment, calibrations are performed using precision test blocks that simulate conditions and serve as reference standards. Different types of test blocks simulate different conditions. The eddy current equipment should be standardized to two reference standards before and during an inspection. Many instruments carry the two standards attached to their frame. . L. & Mixson, K. Use of Eddy Current Conductivity and Hardness Testing to Evaluate Heat Damage in Aluminum Alloys. J Fail. Anal. and Preven. 18, 50–54 (2018). https .Like most test and measurement equipment, eddy current testers need to be periodically calibrated to maintain accuracy. In the case of NDT equipment, calibrations are performed using precision test blocks that simulate conditions .

Eddy Current Testing Instruments for Power Generation. Power generation is critical in almost every aspect of daily function—from schools to hospitals to communication and relaxation. Because of this, nondestructive testing is a .ECT testing equipment for automotive parts and aviation including BKNFX Pre-Multi-Frequency Eddy Current Hardness Separator, BKNET Series Multi-frequency and Multi-filter Eddy Current Flaw Detector, ET-F1 Engine Cylinder Bore Eddy Current Flaw Detector, GTET-02 Cylinder Liner Eddy Current Flaw Testing Machine, Steel Ball Hardness eddy current .4.1.6.2 Effect of Permeability on Eddy Currents.Eddy current testing of ferromagnetic parts is usually limited to . 4.1.6.7 Heat Treat Condition or Hardness.Heat treating (or age hardening) a metal changes its hardness and its . related equipment. In addition, eddy current equipment is portable, with most systems using battery power. Eddy .

Electrical Eddy Current Testing Equipment Digital Portable 60KHz . Introduction . HEC-102 is a kind of eddy current electrical conductivity meter, which is designed for quick & convenient measurement of material property, such as material separate,quality control,material state check and .

Why Should I Use Eddy Current Technology for Hardness Testing? Eddy current testing is a contactless nondestructive method, so analysts don’t have to worry about damaging the asset or wasting any materials or resources. Eddy current testing equipment provides extraordinary sensitivity and accuracy when it comes to finding surface and near .

Product Performance Testing Standard:GB/T 11260-2008 round steel eddy current testing method, GB/T 7735-2004 steel tube eddy Current testing method Longitudinal artificial injury:0.10(depth)×0.10An Industry Leader in manufacturing and supplying Various categories of Microscopes and Hardness testing Equipment Now involve in developing Eddy Current Testing machines . . Eddy Current testing equipment can be used for applications such as cracks detection (discontinuities), measurement of the metal and coating thicknesses, detection of .UniWest offers essential NDT solutions, providing highly engineered products, including Eddy Current Instruments, Eddy Current Systems, Eddy Current Probes, and Ultrasonic Transducers.Whether for manual field inspection, laboratory testing, or integrated in-line production systems, UniWest is your comprehensive resource for tailored testing solutions.

These videos demonstrate how eddy testing equipment serves to test valve cover thread, quick sort by hardness, test for cracks, roller bearing flaws, & more. . Premier Supplier of Eddy Current Test Systems for Newly Manufactured Componentsdiscontinuity on eddy current pattern is shown in figure 4.2. The impedance of a coil can be determined by measuring the voltage across it. In eddy current test equipment, changes in coil impedance can be indicated on a meter or achart recorder or displayed on the screen of a cathode ray tube.

how eddy current testing works

Microhardness testing is the best example of a nondestructive hardness test. Some of the more common NDT test types are described below. Eddy Current Testing. Eddy Current testing utilizes the principal of “electromagnetism” as the basis for conducting examinations. In eddy current testing, a current is introduced to the material.

Why Should I Use Eddy Current Technology for Hardness Testing? Eddy current testing is a contactless nondestructive method, so analysts don’t have to worry about damaging the asset or wasting any materials or resources. Eddy current testing equipment provides extraordinary sensitivity and accuracy when it comes to finding surface and near .

aggregate impact test viva questions

eddy current testing pdf

O invertexto.com é um site gratuito que reúne diversas ferra.

eddy current hardness testing equipment|who does eddy current testing